I-turbine blade ephezulu yokubuyisela umfutho wegesi

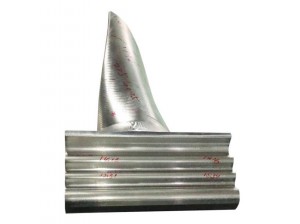

I-TRT BLADE

Amandla aphakathi nendawo weyunithi ye-TRT turbine generator igesi ye-blast furnace.I-turbine blade iyingxenye eyinhloko yesistimu ye-rotor.Insimbi ye-blade ingu-2Cr13 futhi ingaphansi kokwelashwa kokulungiswa.I-blade ihlukaniswe yaba izigaba ezimbili (okungukuthi izigaba ezimbili zama-blade anyakazayo kanye nezigaba ezimbili zama-engeli anyakazayo ama-blade), kuzo ezingama-26 kuyisiteji sokuqala sezindwani ezimile futhi ezingama-30 ziyisigaba sesibili sezindwani ezimile;Kunama-blade anyakazayo angama-27 esiteji sokuqala nama-27 esiteji sesibili anyakazayo.Ijubane lokusebenza le-rotor liyi-3000 rpm (isivinini sokuqala esibucayi siklanyelwe njenge-1800 rpm; isivinini sesibili esibucayi siklanyelwe njenge-6400 rpm).

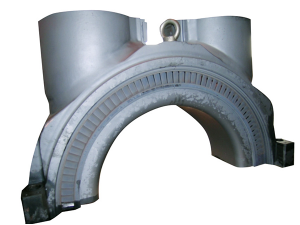

Nakuba uthuli oluningi lwesithando somlilo lungasuswa ngemva kokuchithwa, kusekhona inani elithile lothuli lwesithando somlilo, umhwamuko wamanzi kanye nezinhlobonhlobo zamagesi e-asidi akhiqizwa ngenxa yezinto ezingahlanzekile zokuqhuma kwesithando somlilo, njenge-H2S, HCL, CO2, njll. i-gas phase medium.Ngenxa yokunwetshwa kweyunithi, izinga lokushisa liyancishiswa kancane kancane, futhi igesi ene-asidi iyancibilika ku-condensate, okubangela ukuthi amanzi ane-asidi anamathele endaweni yama-blades, amagobolondo, ama-deflectors nezinye izingxenye isikhathi eside.Ngaphezu kwalokho, ama-ion e-chlorine egesi ngaphansi kokushisa okuphezulu akhululwa, okubangela ukugqwala okukhulu kwama-blades;Ngesikhathi esifanayo, ngenxa yejubane eliphezulu

Ngaphansi kwesimo sokusebenza isikhathi eside ngothuli lwesithando somlilo, izinhlayiya zizoqhubeka zikhiqiza ukungqubuzana kokusika kanye nokungqubuzana okuqondile endaweni eyi-blade egqwalile futhi engenawo amandla, okuholela ekulimaleni okusheshayo kwe-blade.Uma i-blade yonakalisiwe, umthelela oqondile kuyunithi ukusebenza kahle okuphansi nokudlidliza okukhulu.

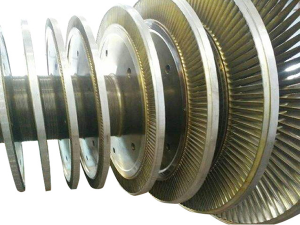

Njengoba i-blade ingagcini nje ngokuba nezindleko eziphakeme zokushintshwa, kodwa futhi idlala indima ebalulekile ekusebenzeni okuphephile nasekukhiqizeni okuqhubekayo kweyunithi, inkampani ibheka ukubaluleka okukhulu kuyo futhi isebenzisa izindlela ezihambisanayo zokuyilungisa nokuyivikela, njengokulungisa i-laser cladding, ukukhanda nokuvikelwa kwe-anti-corrosion, impushana yensimbi yokufafaza ukuvikela kwangaphambili, njll., okunemiphumela ethile.