I-turbine stationary blade diaphragm

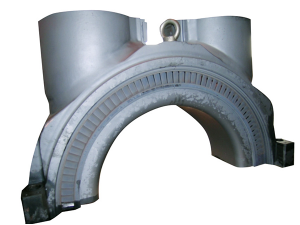

Ngesikhathi senqubo yokukhiqiza i-diaphragm, inkinga eyinhloko ukuxhumana phakathi kwe-blade emile kanye nomzimba we-diaphragm kanye nendandatho yangaphandle.Izidingo zobuchwepheshe zonke zibekwe phambili kule nkinga.Ukuxhumana phakathi kwe-blade emile kanye nomzimba we-diaphragm kanye nendandatho yangaphandle kufanele kube namandla anele, i-diaphragm steam passage kufanele ibe nokuma okuhle kwe-cross-sectional kanye nendawo, indilinga ye-pitch kufanele igxile esikhungweni se-diaphragm, indawo yokungena kanye nemiphetho yokuphuma. i-blade emile kufanele ibe endizeni efanayo, futhi i-diaphragm ecutshunguliwe kufanele ibe nokushelela okwanele, Ukuqinisekisa ukucinana komoya okuhle.Indiza yohlangothi lwe-steam outlet lwendandatho yangaphandle ye-diaphragm ihambisana nendiza yohlangothi lwe-steam outlet yensingo emile ukuze kuqinisekiswe ukuxhumana okuqinile nesilinda.

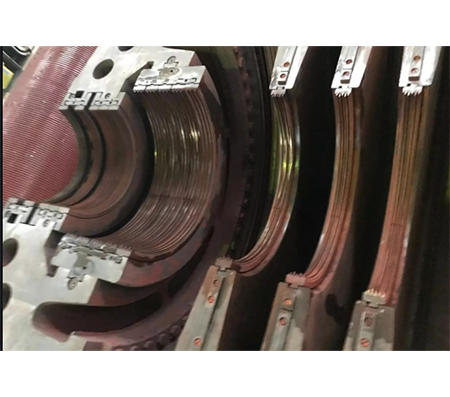

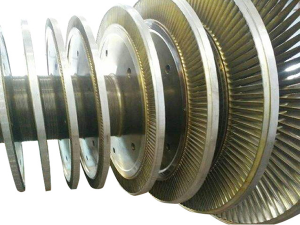

Inhloso ye-diaphragm ye-steam turbine: isetshenziselwa ukulungisa ama-blade amile futhi yakhe izindonga zokuhlukanisa kuwo wonke amazinga e-steam turbine.Ikakhulukazi yakhiwe umzimba we-diaphragm, izindwani ezimile kanye nonqenqema lwangaphandle lwe-diaphragm.I-diaphragm ye-steam turbine diaphragm ifakwe kakhulu ku-diaphragm groove odongeni olungaphakathi lwesilinda noma ifakwe kusilinda kusetshenziswa umkhono we-diaphragm.Njengoba kuboniswe ngezansi:

Kunabasebenzi abangaphezu kuka-20 abasebenza ngobuchwepheshe ku-workshop yokuhlukanisa yenkampani yethu.Laba basebenzi sebeneminyaka engaphezu kweyishumi benza umsebenzi wokukhiqiza nokucubungula ama-partitions, futhi bahlome ngemishini yokuhlola echwepheshile: ama-spectrometer okufunda aqondile, ama-ultrasonic flaw detectors, ama-diameter akhethekile angaphakathi nangaphandle, njll. Ukuze kuqinisekiswe ikhwalithi. kanye nekhono lokukhiqiza lesihlukanisi futhi lihlangabezana nezidingo zokulethwa kwamakhasimende, inkampani ine-lathe ehlukahlukene eqondile, umshini wokushisela ovikelekile wegesi othomathikhi kanye nemishini yokulawula izinombolo ezinkulu, njenge-1.6m, 2.5m kanye ne-4m.